[Note that the spreadsheet calculator have been updated in the

March blog entry above. However all the explanation and information below will still be useful.]

UK microgeneration tariffs

UK microgeneration tariffsFor 35-years Ampair has concentrated on manufacturing battery charging systems – our wind turbines, micro hydro turbines, and solar PV systems. Over the last couple of years the grid-connected version of the Ampair 600 wind turbine has been available but even so we have had relatively few grid-connected clients. We expect this to change over the coming years. A client who is running one of our prototypes recently asked for our advice on the best deal available from the UK electrical utilities for a microgeneration tariff. This caused me to delve into the current tariff deals and this blog entry discusses the results. Even better you can download our handy little spreadsheet calculator that will help you identify the best deal for you. The spreadsheet can be used in other countries.

The UK has one of the most complex grid systems in the world from a regulatory and commercial perspective. In this blog entry I will ignore most of the complexity and just talk about “the utilities”.

There are a bewildering array of tariffs available to clients even before we get into the specialist discussion of microgeneration tariffs. Again I am going to just concentrate on the microgeneration tariffs, and specifically only on the electrical tariffs (because yes, thermal tariffs are coming one day).

The structure of microgeneration tariffsIt used to be that customers on the electrical grid paid the utility for three basic elements:

- a meter charge

- a connection charge

- a tariff per unit of electricity (per kWh) that they import from the grid, i.e. £/kWh import. This is what you pay for normally when you buy electricity, i.e. electricity that you imported into your house from the grid.

In addition to this customers with grid-connected microgeneration have two more elements to consider:

- a tariff per unit of electricity (per kWh) that they export to the grid, i.e. £/kWh export, sometimes known as a feed-in-tariff

- a tariff per unit of renewable electricity that they generate, called a ROC which stands for Renewable Obligation Certificate

Now let”s look at these in more detail because you will need to understand the system to figure out what is the best deal for you.

What is a ROCIn the UK the utilities are forced to buy a certain amount of electricity generated from renewable sources. The quota they must buy is supposed to increase over time. Every generator of renewable electricity is given a Renewable Obligation Certificate (a ROC) as they generate electricity. Then they sell the electricity to the utilities and separately they sell the ROC certificates. The sales take place in an auction process but we don”t need to worry about that – all we need to know is that the renewable electricity we generate has two values, firstly for the electricity itself, and secondly for the ROC. The extra value of the ROC is supposed to help pay for the extra cost of building expensive wind farms and hydro stations rather than cheap coal fired power stations. In your case it helps pay you to install your microgeneration system.

If you have lots of ROCs you can go to the auction and sell them yourself. But if you only have a few you might prefer to sell them to your utility company so as to avoid the administration. You can also sell them to intermediaries who may offer you a higher price than the utilities, and who will then bundle them with other people”s ROCs to make a more attractive auction package. You can only sell ROCs to the intermediaries if your utility has not locked you into a contract which forces you to sell them to the utility. This is what I mean when I talk about “locked ROCs” and “unlocked ROCs”.

One ROC certificate is supposed to be for quite a large chunk of electricity and is worth about £40 - £50 at auction. So in practice it is ordinarily simpler for the microgeneration owner to sell their ROCs to the utility who is prepared to accept partial ROCs and pay a £/kWh fee for them. The utility will then bundle them with lots of other peoples” partial ROCs to make a useful quantity for administrative purposes.

In the future ROCs will get banded and microgenerators will get even more ROCs but let”s not discuss that except to bear in mind that over the next few years there will be more money for the householder from selling their ROCs, which is generally a good thing.

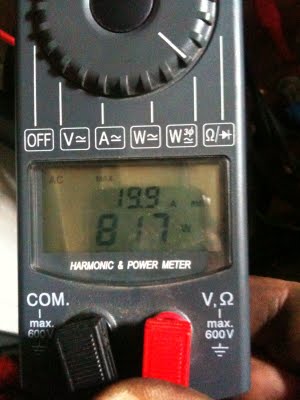

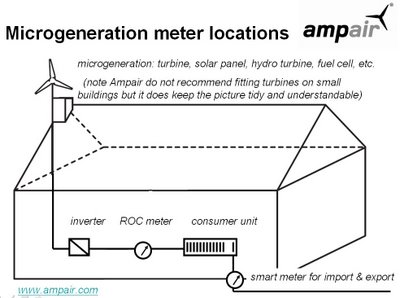

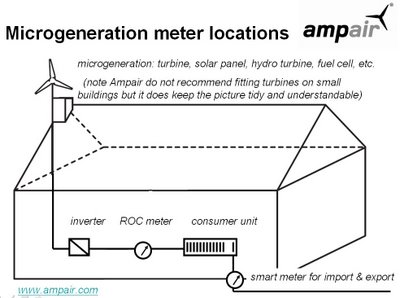

An important thing about ROCs is that they are given for the generation of renewable electricity and it doesn”t matter whether you use that electricity yourself or whether you export it to the grid. But it does mean that you must have an electricity meter in the correct location to count the renewable electricity that you generate. This ROC meter is in a different position than the import meter (see picture). So you can get paid even if you keep all the electricity to yourself !

Electricity metering for an export tariff (feed-in-tariff)When the microgenerator produces electricity the electricity can either be consumed in the premises or any left over must flow out into the grid (please don”t try storing it in batteries if you live in the UK – it”s not a good idea but it”s too big a discussion for this blog entry). This is often called feeding-in to the grid which is why these tariffs can be called a feed-in tariff. The less electricity you consume the more is left over and the more that will flow out into the grid. The technology makes sure that electricity you make is consumed in preference to electricity you import. In the old days electricity that flowed out into the grid would have turned the meter backwards but these days the utilities install meters that will turn in only one direction (in the old days people could steal electricity by rewiring their meters in reverse until anti-theft meters were invented). So unless you change your meter the electricity will still flow out into the grid but it won”t be counted. (By the way be very careful if reading American websites as they often talk about “net metering” as if it was literally turning the meter backwards which it isn”t).

Because of the invention of anti-theft meters a special meter has to be fitted that keeps two totals – the electricity imported and the electricity exported. This is often called a smart meter and some of these bidirectional meters are smart meters, but not all of them. The people you will talk to in the utilities will call all of them smart meters or export meters and it is best just to use the same name as they do so as not to confuse things.

You will still pay your normal amount for the electricity imported. But now we come to the good bit - by law in the UK the electricity companies must offer you a price for the renewable electricity you export. Unfortunately the bad bit is that some of the electricity companies bend the law by offering a price of zero for electricity produced from most renewable microgeneration technologies. So this means they can tell the politicians that they fully support customers who wish to make a cleaner environment, and then they go out and offer a price of zero. The politicians and Ofgem (the energy regulator) aren”t very good at fining the companies for this downright evasive behaviour which is because of something called regulatory capture, i.e. the politicians and regulators tend to do what the utilities want rather than what voters want. If anybody doesn”t believe me I suggest you ring up EON.powergen and ask for an export tariff for hydro microgeneration. Actually things are now better than they used to be and EON.powergen and Scottish Power are pretty much the laggards in this respect. You won”t be able to find anyone on the Scottish Power switchboard who will understand what a microgeneration tariff or a feed-in tariff is (of course I hope they read this blog and are shamed into cleaning up their act – or that Ofgem fine them).

Over the last few years things have improved in this respect but let us discuss another way some companies evade their responsibilities. In order to get paid for exporting electricity to the grid you will need an export meter. Actually getting an export meter fitted can be a very daunting prospect for a customer who is struggling to cope with the terminology and the technology. Helpfully EON.powergen will not install an export meter for you and will not tell you how to get one fitted. So although EON.powergen will pay you £0.10 per kWh of solar electricity you export, most clients will never get paid because they”ll never be able to get an export meter fitted. Remember that EON.powergen discriminate against electricity from wind, hydro, and fuel cells and will pay zero for that. Anyone could be forgiven for thinking that some utilities were really going out of their way to be difficult. I should point out that EON are a German company and have cooperated enthusiastically with the German government to support a feed-in-tariff in Germany so it is obviously possible for EON to do it if they want to, it”s just that they obviously don”t want to enough in the UK. Maybe German politicians are a more determined lot than British politicians, who knows. Lest anyone think I am beating up on EON you should try telephoning Scottish Power because I still haven”t managed to figure out the secret words to find anyone who can talk to me (and I”ve tried please, and I”ve tried talking to managers on three different phone lines). Another company who are somewhat difficult about export meters are British Gas / Centrica who will also not tell you how to get an export meter fitted and will not fit one for you. By the way BG Centrica will pay you a huge 5p per kWh you export which is getting pretty close to that magic zero I was talking about earlier.

Whilst I am on the subject of export meters if any company tries telling you that they are not permitted to arrange an export meter I am afraid it is absolute nonsense. Yes I fully understand that there are huge regulatory issues around the subject of export meters but some companies manage to be helpful and still comply with the spirit of the regulations so it can be done if they try. Congratulations to Scottish and Southern Energy for showing the way in this respect because not only will they fit an export meter but they will also do it for free. It took them about two weeks to turn up and fit mine when I asked them as an experiment (I figured I”d better try it out on myself before I sent them to a client). It took the technician about half an hour to fit the export meter.

How much will you be paidSome companies have decided to make the customer”s life easier by paying a lot for the ROCs but paying nothing for the actual exported electricity. This means that you don”t need an export meter, they don”t worry about the hassle of fitting an export meter, nobody has the cost of an export meter, and everybody is happy provided they pay you enough. This is what Good Energy and Ecotricity do and they will both pay you around £0.10/kWh for the ROC value which as we will see later are probably the best microgeneration deals available in the UK.

Although RWE.npower will not advise you on fitting an export meter and will not fit one for you they have a different way of making the customer”s life easier. If you want they will assume that you export 50-60% of the electricity you produce and pay you an export tariff for that amount, plus a small amount for the ROC. So they pay £0.035/kWh for the ROC and £0.10 - £0.12/kWh for half of the power as your export tariff. This works out slightly stingier than the Good Energy and Ecotricity deals. Perhaps their import tariffs are slightly cheaper in which case they may still be a better utility to choose as your supplier.

With Scottish and Southern it is a similar deal to RWE.npower except that they fit a meter for free. The actual rates they give you are higher for the ROC and lower for the export tariff compared with RWE.npower but the total benefit tends to work out about the same for most people. On balance I tend to prefer the Scottish and Southern package versus the RWE.npower package for two reasons. Firstly if people have real meters then they are incentivised to minimise electricity consumption which is the best way to save money and look after the environment – the assumptions made in “profiling” discriminate against people learning better behaviour. Secondly Scottish and Southern Energy don”t discriminate between different types of renewable electricity (except for one of their tariffs, discussed below).

Let me discuss the discrimination issue further. Here at Ampair we manufacture wind turbines in the UK and we sell them to British customers (and we export them all over the world). Then a utility will pay a feed-in tariff of say 10p per kWh for electricity from one of our wind turbines but it will pay 12p per kWh for electricity from a solar panel. Almost all solar panels sold in the UK are imported from Germany, Spain or China and I do not see why we should be encouraging British consumers to buy imported solar panels rather than domestic wind turbines. What we should really do is to force the utilities to offer the same tariff for all technologies and then let the client decide which is the correct technology for the client”s site. In this I am at least principled unlike the German government which has launched their solar industry using a tariff that discriminates in favour of their domestic solar manufacturers and against British small wind turbine manufacturers. I am also annoyed in this respect by Scottish and Southern Energy who should know better, and are offering 20p per kWh but only for solar.

To put all these numbers in perspective the feed-in tariff for solar microgeneration in Germany is about 40p per kWh. A shame the Germans discriminate against small wind turbines or we would have a nice business over there, or in Spain, or in France. Oh and compare the export tariffs with the import tariffs – if the utilities could organise their billing systems they would be making a profit out of you producing electricity which they buy from you at a lower cost than they sell it to your neighbour, i.e. your capital investment would be subsidising them. Something”s not right here and it won”t be right until the export tariff (excluding the ROC element) is at least equal to the import tariff as a minimum.

Understanding your utility partnerI prefer to think of the utilities as partners rather than suppliers as it gets me in the right frame of mind. Even though I may sometimes be disappointed by their behaviour they do have an important job to do. For example they have to give you continuity of supply when your microgeneration system isn”t producing, and they have to handle all the administration, and they have to pay you some money. If you are lucky they may even have to pay you more than you pay them.

Choosing between them can be difficult. Even the first step of getting the relevant information out of all of them is practically impossible – as I”ve said before I challenge you to get past the Scottish Power switchboard. As a general rule their websites are unhelpful. Some have tucked microgeneration away in a corner of their energy efficiency section, but even then they don”t give important information such as tariff rates and telephone numbers. Some of them make assumptions that are wrong or unhelpful. And some don”t exist at all. Trying to phone the telephone numbers which can be found is depressing as they are almost all routed to answering machines or are disconnected. So I also tried ringing all the switchboards just like a standard client would. After a great deal of perseverance I was able to get through to the right specialist department most of the time. Typically it took about four – six telephone calls per company and about 45-60 minutes on hold plus a lot of coaxing on my part. I have admitted failure with Scottish Power as my life is too short. With EDF they get the runner-up prize for the worst switchboard as their people refused to talk to me unless I was in an EDF region. In the end I gave up with the EDF switchboard and used a number I found elsewhere on the web.

Once I had got through to the specialist department I got the data I needed and explained that I would be putting it on the Ampair blog. It turned out I already knew some of the people from various industry committees and most of them are a good bunch. In general the specialist microgeneration teams are small and include pretty committed people who are not very well supported by the organisations they are in. Don”t get mad with them as they are mostly trying to change things for the better. They are also supposed to be their organisations experts and I am afraid that a substantial fraction of them do not yet know sufficient to advise their organisations authoritatively which is worrying – they tend to be staffed by the less experienced personnel. The four organisations who stood out for their better level of knowledge were Ecotricity, Good Energy, Scottish and Southern Energy, and RWE.npower.

I have made a note of all of the microgeneration tariff information, including the tariff names and the telephone numbers of the specialist departments on the attached spreadsheet. This alone should be a huge step forwards if you want to compare your options and make any further enquiries. I”ve sent this to those utilities which I had the email addresses of and updated it where I got given corrections. I have not bothered to record website details as most were so appalling, with one or two exceptions.

Excel version of Ampair tariff information + calculator:UK_microgeneration_export_tariffs.xlsPDF version of Ampair tariff information + calculator:UK_microgeneration_export_tariffs.pdfI fully understand the issues that the utilities are grappling with, including the ones they don”t want to talk about in public. This is already a long enough blog entry so I”ll discuss that another time. In the meantime let”s get on to the next topic, that of actually choosing your utility partner

Choosing your utility partnerAssuming you are at least partly motivated by financial considerations you will want to try and understand which utility is giving you the best deal. The second page of the spreadsheet is a calculation tool which I have put together to cope with most circumstances and will explain next. I have locked the spreadsheets to prevent you deleting calculation cells by accident, but you can change data in some yellow cells which I have deliberately left unlocked.

Firstly if you have no connection to the electrical grid then you should choose the Good Energy “homegen offgrid” tariff. This means you rely on batteries.

Secondly assuming you are like most UK customers you are a grid-connected client. So look in the top right corner of the second page of the spreadsheet where there are some bright yellow cells. Enter values into these:

- Enter your average annual total consumption in kWh (which may be called “units” on your electricity bill). A typical UK house might use about 3,000 – 6,000 kWh/yr but it can be a lot less and I use about 1,200 kWh/yr in a 2-bed maisonette.

- Enter a default import rate. This just helps put all the utilities into perspective. It will probably be in the range £0.12/kWh - £0.15/kWh at the moment.

- Select your microgeneration technology. You will need to put your cursor on this cell and select from wind, solar (PV), hydro, or fuel cell. Some of the tariffs are only available for some of the technologies and so depending on what you select the calculation tool will “grey out” the tariffs that cannot be used for your technology. If you want to have multiple technologies I am afraid the utilities aren”t so good at coping with you unless you choose one of the tariffs that is available for “all technologies”.

- Enter your average annual total generation in kWh. If you have a 1kW microwind turbine and are in a city this might be as low as 100kWh but if you have a 6kW small wind turbine and live on a windy hill this might be as high as 8,000 kWh/yr. So this depends on your technology of choice and on your location. If you are not sure then your microgeneration installer should be able to advise you. Alternatively you could look at the

Encraft website for some handy

prediction calculators for the various technologies. Please do not telephone Ampair – although we make wind turbines we are not an advice line and instead you should telephone our

distributors who organise installation if you want to buy one of our turbines.

- Enter your likely export fraction in %. If you are installing a lot of microgeneration compared to your consumption then this might be as high as 75%. If your microgeneration is relatively small compared to consumption then it may be nearer to 25%. If in doubt try 50%.

Now scan down the spreadsheet and you will see that the white cells are the likely size of your annual electricity bill after taking into account the electricity you don”t need to buy as well as the money you are paid for ROCs and electricity you export. In almost all circumstances I find that Good Energy and Ecotricity tie for joint first place, and that RWE.npower and Scottish and Southern Energy tie for joint second place which is why I have put these four at the top of the spreadsheet.

To improve the accuracy of your prediction and to allow you to update the spreadsheet as new tariffs become available you can also enter data into the light yellow cells. It is probably worth contacting the utilities of interest to find out the applicable standard (i.e. import) tariffs as this may swing the selection between the different utilities (especially if you also buy gas from the same utility).

These calculations do not take into account the cost of fitting an export meter but the better four utilities have structured their tariffs so that this is essentially zero as discussed above. If a company insists on you buying an export meter and is unhelpful then it is probably a pretty good indication that they don”t deserve your business.

With RWE.npower you can sign up to “juice” which ensures that the electricity you import comes from renewable sources. They will not charge you extra for this and any RWE.npower customer can sign up (spread the word). Using renewable sources is a given if you buy from Good Energy or Ecotricity but often their import tariffs are a bit more expensive. I am not sure of the situation with Scottish and Southern Energy in this respect but they are definitely very committed to their large scale renewable energy projects so they deserve support as well. A lot of people criticise the small print in the commitments of these four companies but at least they are trying.

SummaryThis is complicated but the little spreadsheet calculator makes it a lot easier. A car is complicated as well but society teaches us about cars from the day we are born – one day society will teach us all about using and conserving energy from the day we are born. In the meantime I hope this helps explain your options.

The four utilities I put at the top of the spreadsheet are also the four who I find most supportive in all the industry meetings and discussions which is a welcome surprise. That doesn”t mean we always agree with each other.

If you think these feed-in-tariffs and ROC prices are too low contact your MP and ask when we will have a microgeneration feed-in tariff of 40p/kWh common to all technologies including wind and hydro. Don”t take no for an answer and don”t allow your MP to be evasive on the need for the tariff to be a common rate for all the microgeneration technologies. Don”t be fobbed off with delays. There”s an election coming quite soon and you can remind your MP that they work for you and not the other way around.

Also ask when Ofgem are going to fine the evasive utilities so as to drive the message home that this is getting serious.

I hope that soon this spreadsheet is out of date and the worse performing utilities have improved dramatically.

Excel version of Ampair tariff information + calculator:UK_microgeneration_export_tariffs.xlsPDF version of Ampair tariff information + calculator:UK_microgeneration_export_tariffs.pdfLabels: Ampair tariff calculator, export meter, export tariffs, feed in tariffs, IEC 61400-2 small wind turbines edition 3 (CDV), net metering, ROC, smart meter, UK microgeneration tariffs